Do sudden absences sometimes affect your ability to maintain consistent quality and productivity results due to those

sole resources having all the answers to manufacturing and scheduling problems? Are those individuals overloaded with

work with no clear way to delegate responsibility when needed? If so you might have a Tribal Knowledge issue affecting

the scalability of your business.

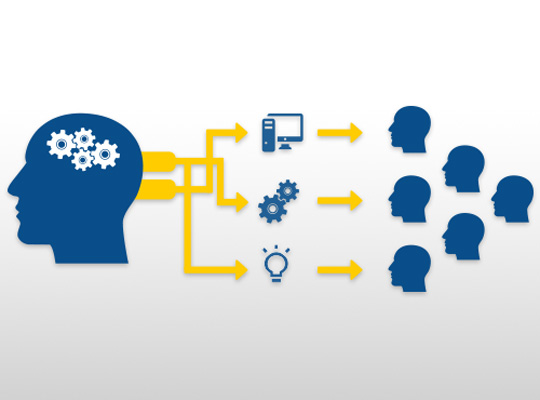

“Tribal Knowledge is any unwritten information that is not commonly known by others within a company”. Tribal Knowledge, as defined by Wikipedia, is commonly used when referencing information that may need to be known by others, in order to produce a quality product or service. This information may be key to quality and performance, but it may also be totally incorrect.

Tribal Knowledge can be a barrier to corporate growth. We will explore these issues in an industry that relies on the experience of people who actually run the machines and sustain operations. A serious problem is that management is often unaware of the extent of Tribal Knowledge in the organization, therefore not understanding the potential risk to the overall operation and profitability.

Explore the Tribal Knowledge GAP in your company

Plastics processors often hit a growth plateau when team members, absolutely critical to business work flow, have knowledge that is not documented and cannot be replaced. These individuals are often the owners of the business or top management and often find themselves in key roles such as production planning and quoting of new work. Not having the ability to easily replace these key employees may create a bottle neck in the organization. This situation will place undue stress on the owners, who may seldom be able to take vacations, and may affect the overall market value of the business.

Aside from the owners of a plastics manufacturing business, critical resources are often identified that have become irreplaceable and inadvertently holds information hostage, preventing growth.

Explore the Tribal Knowledge GAP in your company

A One-Hour Consultation is the first step towards controlling your company’s future

1. Sudden Absence, Vacations or Illness:

Tribal knowledge proliferates when new employees are informally trained by veteran colleagues. The knowledge passed on by On-The-Job-Training, by a co-worker, may result in passing on incorrect knowledge and techniques. The results may inflict risks to your product, service and quality. Improper training may lead to a waste of raw materials, avoidable equipment breakdowns and improperly optimized equipment leading to reduced plant & machine capacity.

When a skilled employee leaves the organization or becomes suddenly unavailable for any reason, the Tribal Knowledge gap can bring quality operations to a grinding halt.

2. Often Tribal Knowledge is incorrect:

In plastics processing, veteran setup operators often possess the core knowledge for “best run times” for specific jobs. Setting up the machinery may be based on a combination of previous experiences including instinct and his prior On-The-Job-Training by another setup operator.

Setups are often performed differently in molding and extrusion operations, documentation for each production line is required for proper setups including actual run times, machine speeds, reject rates, mold or die efficiency by machine. Setup variations can lead to inconsistent results and make it difficult to standardize productivity, extremely difficult to pinpoint, address and take the corrective actions necessary to improve efficiency and profitability.

This can be misleading if actual run times, machine speeds, reject rates, mold or die efficiency by machine is not documented for each production line. Proper setups must be tracked for time required and documented for each machine. Setups are often performed differently in molding and extrusion operations, depending on which operator performs the task. Each person, with his own understanding of what he or she perceives as best practice or best performance, can lead to inconsistent results. These setup variations make it difficult to standardize productivity, extremely difficult to pinpoint, address and take the corrective actions necessary to improve efficiency and profitability.

3. Hoarding Information and Resources by Employees:

Employees, concerned with job security, may relish being the only ones with knowledge to manage certain processes, perform specific job functions or be depended on to resolve problems. This job security complex will prevent other employees from taking over their functions, learn the process and create additional depth of knowledge in production.

Often these employees will be the last ones to adopt a new process or system that could help them and the organization perform at a higher operating level. Beware of an over-reliance on complex spreadsheets that only a few employees can understand, update and maintain.

The production planner in every production process, including plastics processing, is one of the most critical resources. The production planner essentially controls the company’s throughput and has a significant impact on production capacity, profitability and on-time delivery. This employee is almost always well-intentioned but is often overwhelmed by all the material requirements, personnel constraints and constant customer priority changes. Without real-time data and the necessary intuitive tools on hand, the planner’s effectiveness is reduced.

The planner has tremendous responsibility and this high-stress position allows for very little margin for error. He or she must track and manage many variables, ranging from MRP requirements, raw materials on order and their scheduled arrival times. They must track machine setup times, production lead times and production efficiency based on past performance in conjunction with specific equipment. These individuals are often the most knowledgeable in the organization and keep many balls in the air at once. They affect your company’s ability to quickly confirm orders, take on more business and improve profits. Probably, the most critical position in the company with the capacity to negatively affect profits, by falling ill or leaving, is the production scheduler.

A serious problem is that management is often unaware of the extent of Tribal Knowledge in the organization, therefore not understanding the potential risk to the overall operation and profitability.

4. When is it Time to Challenge the Status Quo?

In the early years of an organization’s history, companies relied almost exclusively on Tribal Knowledge. Surrounding oneself with leaders and people able take initiative was required for growth and to remain profitable. These employees are an important attribute for corporate success. A combination of employees with good attendance, low turnover and dedication is an employer’s dream.

Often, senior management fails to see warning signs that this model doesn’t scale as the business grows without adding additional resources. This becomes evident as the business expands rapidly without formalizing its business processes and investing in an enterprise-wide solution.

Presidents, owners, executives and managers may be unaware that there are industry-specific, highly specialized business process experts armed with extensive molding and extrusion shop floor optimized solutions to simplify the overall workflow while securing the knowledge and techniques that have been learned over the years.

Ask yourself, does only “Bob” know how to quote or set up that job, manage blanket orders, confirm orders quickly or make machine or material substitutions? If so, you likely have just have uncovered a real Tribal Knowledge problem in your business. If you see inconsistency in quality, rejects, material usage or line speed variations from shift to shift, or between different employees, as you review the overall operation, you might just have uncovered another Tribal Knowledge situation.

If managers spend the better part of their day interacting only with other managers in meetings and constantly analyzing and compiling spreadsheets, or doing inventory adjustments, you might just have uncovered another Tribal Knowledge situation.

The answers lie in your overall ability to document all your processes and procedures into a simple repetitive workflow that can be followed to a tee each and every single time and openly shared throughout the organization. In addition all of your production, bill of materials and engineering information for best results should be generated and accompany every work order. Once these are established based on best production performance to the knowledge of your best personnel, you must track the outcomes versus these benchmarks in the manufacturing process.

It is imperative that you must be able to track performance for each operation for standard to actual production efficiency and profitability in the following major areas: Setup times, Machine times, Labor and Material utilized, Run rates achieved, Scrap Generated, etc…

Finally armed with this information you must establish daily shift targets and assign responsibility to managers to analyze what happened, what adjustments to standards need to take plan in order to better estimate sales prices, production time, tool efficiencies by machine and true material needed in the future. These few steps and the newfound ability to better anticipate what can be expected in future production runs in both human and material requirements and production capacity will serve invaluable if shared among team members and help insulate the business against sudden loss of resources and help sustain growth objectives.

Written by Rick Dunne, ERP Expert for Plastics

CyFrame International Enterprises is completely dedicated to helping growth-oriented molders and extrusion operations to implement simple best practice production-oriented management software solutions. Our staff of experts is available to help you implement an efficient software solution to take the next step for growth and increased profitability through expert hands-on process analysis.